Hydrofluoric acid

| Hydrofluoric acid | |

|---|---|

|

|

|

Other names

fluoric acid; fluorhydric acid

|

|

| Identifiers | |

| CAS number | 7664-39-3 |

| EC number | 231-634-8 |

| RTECS number | MW7875000 |

| Properties | |

| Molecular formula | HF |

| Molar mass | not applicable (see hydrogen fluoride) |

| Appearance | Colorless solution |

| Density | 1.15 g/mL (for 48% soln.) |

| Melting point |

not applicable |

| Boiling point |

not applicable |

| Solubility in water | Miscible. |

| Acidity (pKa) | 3.15 [1] |

| Hazards | |

| MSDS | duPont MSDS |

| EU Index | 009-003-00-1 |

| EU classification | Very toxic (T+) Corrosive (C) |

| R-phrases | R26/27/28, R35 |

| S-phrases | (S1/2), S7/9, S26, S36/37, S45 |

| NFPA 704 |

0

4

2

COR

|

| Flash point | Non-flammable |

| Related compounds | |

| Other anions | Hydrochloric acid Hydrobromic acid Hydroiodic acid |

| Related compounds | Hydrogen fluoride |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa) |

|

| Infobox references | |

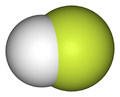

Hydrofluoric acid (HF) is a solution of hydrogen fluoride in water. While it is extremely corrosive and difficult to handle, in the chemical sense, it is a weak acid.[2] Hydrogen fluoride, often in the aqueous form as hydrofluoric acid, is a valued source of fluorine, being the precursor to numerous pharmaceuticals such as fluoxetine (Prozac), diverse polymers such as polytetrafluoroethylene (Teflon), and most other synthetic materials that contain fluorine.

Hydrofluoric acid is best known to the public for its ability to dissolve glass by reacting with SiO2 (silicon dioxide), the major component of most glass, to form silicon tetrafluoride gas and hexafluorosilicic acid. This property has been known since the 17th century, even before hydrofluoric acid had been prepared in large quantities by Carl Wilhelm Scheele in 1771.[3] Because of its high reactivity toward glass, hydrofluoric acid must be stored (in small quantities) in polyethylene, Teflon, or (originally) Gutta-percha containers. It is also unique in its ability to dissolve many metal and semimetal oxides.

The danger in handling hydrofluoric acid is extreme, as skin saturation with the acid in areas of only 25 square inches (160 cm2) may be relatively painless, yet ultimately fatal. High concentrations of hydrofluoric acid and hydrogen fluoride gas will also quickly destroy the corneas of the eyes.

Contents |

Acidity

Hydrogen fluoride ionizes in aqueous solution in a similar fashion to other common acids:

- HF + H2O

H3O+ + F−

H3O+ + F−

Due to its low degree of ionization in dilute solution, hydrofluoric acid is the only hydrohalic acid that is not considered a strong acid.

When the concentration of HF approaches 100%, the acidity increases dramatically due to the following equilibrium:

- 2 HF

H+ + FHF−

H+ + FHF−

The FHF− anion is stabilized by the very strong hydrogen–fluorine hydrogen bond.

Production

In industry, hydrofluoric acid is produced by treatment of the mineral fluorite (CaF2) with concentrated sulfuric acid. When combined at 265 °C, these two substances react to produce hydrogen fluoride and calcium sulfate according to the following chemical equation:

- CaF2 + H2SO4 → 2 HF + CaSO4

Although bulk fluorite is a suitable precursor, most HF is produced as a by-product of the production of phosphoric acid, which is derived from the mineral apatite. Apatite sources typically contain a few percent of fluorite. The acid hydrolysis of fluorite-containing minerals generates an impure gas stream consisting of sulfur dioxide (from the H2SO4), water, and HF, as well as particulates. After separation from the solids, the gases are treated with sulfuric acid and oleum to afford anhydrous HF. Owing to the corrosive nature of HF, its production is accompanied by the dissolution of silicate minerals, and, in this way, significant amounts of fluorosilicic acid is generated.[4]

Uses

Oil refining

In a standard oil refinery process known as alkylation, isobutane is alkylated with low-molecular-weight alkenes (primarily a mixture of propylene and butylene) in the presence of the strong acid catalyst hydrofluoric acid. The catalyst is able to protonate the alkenes (propylene, butylene) to produce reactive carbocations, which alkylate isobutane. The reaction is carried out at mild temperatures (0 and 30 °C) in a two-phase reaction. It is important to keep a high ratio of isobutane to alkene at the point of reaction to prevent side reactions that lead to a lower octane product, so the plants have a high recycle of isobutane back to feed. The phases separate spontaneously, so the acid phase is vigorously mixed with the hydrocarbon phase to create sufficient contact surface.

Production of organofluorine compounds

The principal use of hydrofluoric acid is in organofluorine chemistry. Many organofluorine compounds are prepared using HF as the fluorine source, including Teflon, fluoropolymers, fluorocarbons, and refrigerants such as freon.[4]

Production of fluorides

Most high-volume inorganic fluoride compounds are prepared from hydrofluoric acid. Foremost are Na3AlF6, cryolite, and AlF3, aluminium trifluoride. A molten mixture of these solids serves as a high-temperature solvent for the production of metallic aluminum. Given concerns about fluorides in the environment, alternative technologies are being sought. Other inorganic fluorides prepared from hydrofluoric acid include sodium fluoride and uranium hexafluoride.[4]

Etchant and cleaning agent

The ability of hydrofluoric acid to dissolve metal oxides is the basis of several applications. It removes oxide impurities from stainless steel, a process called pickling, and silicon wafers in the semiconductor industry. In similar manner, it is also used to etch glass. A 5% to 9% hydrofluoric acid gel is also commonly used to etch all ceramic dental restorations to improve bonding.[5] For similar reasons, dilute hydrofluoric acid is a component of household rust stain remover and in car washes in "wheel cleaner" compounds.[6]

Hydrofluoric acid attacks glass by reaction with silicon dioxide to form gaseous or water-soluble silicon fluorides. This dissolution process proceeds as follows:

- SiO2 + 4 HF → SiF4 (g) + 2 H2O

- SiO2 + 6 HF → H2SiF6 + 2 H2O

Due to its ability to dissolve iron oxides as well as silica-based contaminants, hydrofluoric acid is used in pre-commissioning boilers that produce high-pressure steam.

Niche applications

Due to its ability to dissolve oxides, hydrofluoric acid is useful for dissolving rock samples (usually powdered) prior to analysis. In similar manner, this acid is used in acid macerations to extract organic fossils from silicate rocks. Fossiliferous rock may be immersed directly into the acid, or a cellulose nitrate film may be applied (dissolved in amyl acetate), which adheres to the organic component and allows the rock to be dissolved around it.[7]

Diluted hydrofluoric acid (1 to 3 %wt.) is used in the petroleum industry in a mixture with other acids (HCl or organic acids) in order to stimulate the production of water, oil, and gas wells specifically where sandstone is involved.

Safety

Hydrofluoric acid is an extremely corrosive liquid and is a contact poison. It should be handled with extreme care, beyond that accorded to other mineral acids. Owing to its low dissociation constant, HF penetrates tissue more quickly than typical acids. Because of the ability of hydrofluoric acid to penetrate tissue, poisoning can occur readily through exposure of skin or eyes, or when inhaled or swallowed. Symptoms of exposure to hydrofluoric acid may not be immediately evident. HF interferes with nerve function, meaning that burns may not initially be painful. Accidental exposures can go unnoticed, delaying treatment and increasing the extent and seriousness of the injury.[8]

Once absorbed into blood through the skin, it reacts with blood calcium and may cause cardiac arrest. Burns with areas larger than 25 square inches (160 cm2) have the potential to cause serious systemic toxicity from interference with blood and tissue calcium levels.[9] In the body, hydrofluoric acid reacts with the ubiquitous biologically important ions Ca2+ and Mg2+. Formation of insoluble calcium fluoride is proposed as the etiology for both precipitous fall in serum calcium and the severe pain associated with tissue toxicity.[10] In some cases, exposures can lead to hypocalcemia. Thus, hydrofluoric acid exposure is often treated with calcium gluconate, a source of Ca2+ that sequesters the fluoride ions. HF chemical burns can be treated with a water wash and 2.5% calcium gluconate gel, although dont get too carried away with trying to stick to the 2.5% recommended, too much is better than not enough in this case.[11][12][13] or special rinsing solutions.[14][15] However, because it is absorbed, medical treatment is necessary;[9] rinsing off is not enough. In some cases, amputation may be required.

Hydrogen fluoride is generated upon combustion of many fluorine-containing compounds such as products containing Viton and polytetrafluoroethylene (Teflon) parts. Hydrogen fluoride converts immediately to hydrofluoric acid upon contact with liquid water.

See also

- Vapour phase decomposition

References

- ↑ Jolly W.L. (1984) Modern Inorganic Chemistry, McGraw-Hill, p.177

- ↑ Ayotte, P; Hébert, M; Marchand, P (Nov 2005). "Why is hydrofluoric acid a weak acid?". J. Chem. Phys. 123 (18): 184501. doi:10.1063/1.2090259. PMID 16292908.

- ↑ Greenwood, Norman N.; Earnshaw, A. (1984), Chemistry of the Elements, Oxford: Pergamon, p. 921, ISBN 0-08-022057-6

- ↑ 4.0 4.1 4.2 J. Aigueperse, P. Mollard, D. Devilliers, M. Chemla, R. Faron, R. Romano, J. P. Cuer, “Fluorine Compounds, Inorganic” in Ullmann’s Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, 2005

- ↑ Powers, John M. Powers. Craig's Restorative Dental Materials, 12th Edition. C.V. Mosby, 022006. 10.5.3

- ↑ Strachan, John (January, 1999). "A deadly rinse: The dangers of hydrofluoric acid". Professional Carwashing & Detailing. http://www.carwash.com/article.asp?IndexID=4230101. Retrieved 2006-08-30.

- ↑ Edwards, D. (1982). "Fragmentary non-vascular plant microfossils from the late Silurian of Wales". Botanical Journal of the Linnean Society 84 (3): 223–256. doi:10.1111/j.1095-8339.1982.tb00536.x.

- ↑ Yamashita M, Yamashita M, Suzuki M, Hirai H, Kajigaya H (2001). "Ionophoretic delivery of calcium for experimental hydrofluoric acid burns". Crit. Care Med. 29 (8): 1575–8. doi:10.1097/00003246-200108000-00013. PMID 11505130.

- ↑ 9.0 9.1 "Recommended Medical Treatment for Hydrofluoric Acid Exposure" (PDF). Honeywell Specialty Materials. http://www51.honeywell.com/sm/hfacid/common/documents/HF_medical_book.pdf. Retrieved 2009-05-06.

- ↑ Hoffman, Robert S., Lewis S. Nelson, Mary Ann Howland, Neal A. Lewin, Neal E. Flomenbaum, and Lewis R. Goldfrank. Goldfrank's Manual of Toxicologic Emergencies. New York: McGraw-Hill Professional, 2007, p. 1333

- ↑ el Saadi MS, Hall AH, Hall PK, Riggs BS, Augenstein WL, Rumack BH (1989). "Hydrofluoric acid dermal exposure". Vet Hum Toxicol 31 (3): 243–7. PMID 2741315.

- ↑ Roblin I, Urban M, Flicoteau D, Martin C, Pradeau D (2006). "Topical treatment of experimental hydrofluoric acid skin burns by 2.5% calcium gluconate". J Burn Care Res 27 (6): 889–94. doi:10.1097/01.BCR.0000245767.54278.09. PMID 17091088.

- ↑ "Calcium Gluconate Gel as an Antidote to HF Acid Burns". Northwestern University. http://www.research.northwestern.edu/ors/emerg/firstaid/calglugel.htm. Retrieved 2008-01-03.

- ↑ Hultén P, Höjer J, Ludwigs U, Janson A (2004). "Hexafluorine vs. standard decontamination to reduce systemic toxicity after dermal exposure to hydrofluoric acid". J. Toxicol. Clin. Toxicol. 42 (4): 355–61. doi:10.1081/CLT-120039541. PMID 15461243.

- ↑ "News & Views". Chemical Health and Safety 12 (5): 35–37. September-October 2005. doi:10.1016/j.chs.2005.07.007.

External links

- International Chemical Safety Card 0283

- National Pollutant Inventory - Fluoride and compounds fact sheet

- NIOSH Pocket Guide to Chemical Hazards

- CID 14917 from PubChem (HF)

- CID 144681 from PubChem (5HF)

- CID 141165 from PubChem (6HF)

- CID 144682 from PubChem (7HF)

- Hydrofluoric Acid Burn, The New England Journal of Medicine Acid burn case study